Table of Contents

Introduction

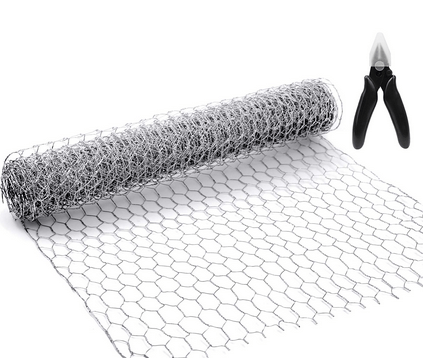

Visualize a substance so simple, yet so extraordinarily versatile that it has long been a mainstay in both urban and rural agriculture. It is the unsung hero of vegetable gardens, the protector of thriving chicken coops, and the key component of a gazillion do-it-yourself crafts. Yes, we are referring to the humble yet incredibly powerful chicken wire. Our houses and gardens have been intricately intertwined with this seemingly straightforward mesh of galvanized steel, which provides answers to issues we were unaware we had. Come along for a tour through the intriguing world of chicken wire, where imagination meets utility and a little roll of wire can change your space in ways you never would have thought possible.

Uses of chicken wire

- Poultry Enclosures

- Gardening and Landscaping

- DIY Projects

- Temporary Fencing

- Animal Proofing:

- Home Improvement

Origins

Poultry netting, sometimes known as chicken wire, dates back to the late 1800s. It was created as a workable solution for poultry farmers who were having trouble keeping their hens safe and contained. The early patterns were straightforward wire meshes, frequently composed of steel, without the hexagonal pattern that defines contemporary chicken wire.

The different types and sizes of chicken wire available in the market.

It is versatile and available in a range of sizes and varieties to meet a variety of requirements. Here is a summary of the various styles and dimensions of wire that are currently on the market:

- Hexagonal Wire Chicken: The mesh pattern of the most popular kind of wire is hexagonal. In general fencing applications as well as chicken farming, this traditional style is extensively utilized. It comes in a range of diameters, with the typical mesh sizes being 1/2 inch to 2 inches. The intended purpose of the wire may also affect its gauge.

- Chicken wire coated in PVC: The polyvinyl chloride (PVC) coating on PVC-coated wire is applied on top of the galvanized wire. This coating increases the wire’s longevity and offers more corrosion protection. Because PVC-coated wire comes in a variety of colors, it is more aesthetically pleasant and appropriate for a range of settings.

- Strong, Sturdy Chicken Wire: Stronger structure and thicker wires characterize heavy-duty wire. This kind of wire works well for more substantial uses, such making sturdy fencing for garden enclosures or providing protection from larger animals. There are different mesh sizes and larger gauges of heavy-duty wire available.

- Stainless Steel Wire for Chicken: Some chicken wire is composed of stainless steel for improved resistance to corrosion. It is made of stainless steel is strong, resilient, and ideal for use in corrosive or challenging conditions. When there is a risk of chemical or salt exposure, it is frequently utilized in maritime environments.

- Wire Mesh Welded: Welded wire mesh is frequently used in place of wire, despite not having the same classic hexagonal design. It is made by joining vertical and horizontal wires together with welding. Compared to woven chicken wire, welded wire mesh offers a stronger and more robust framework.

- Chicken Wire with Mini Mesh: The mesh sizes of mini-mesh wire are usually smaller, varying from 1/4 inch to 1/2 inch. When further defense against tiny pests or birds is needed, this kind of wire is appropriate. In gardening, it’s frequently used to shield smaller plants or seedlings.

- Fencing for gardens and rabbits: Particularly made for gardening or rabbit fencing, chicken wire may have features suited to those uses. To meet the unique requirements of garden protection or to construct enclosures for rabbits and other tiny animals, it may be available in a variety of heights and mesh sizes.

- Adaptable Netting for Wire: Certain types of wire are made to be extremely flexible so they may fit into a variety of asymmetrical shapes and contours. This kind of wire works well for crafts, do-it-yourself projects, and other uses where flexibility is important.

To make sure that the type and size of wire chosen match certain specifications, it is important to take into account aspects like the intended usage, the size of the poultry or animals being contained, and the environmental circumstances.

Evolution in the 19th Century:

By the middle of the 1800s, there was a rising need for a productive way to enclose chickens. Farmers required a material that permitted ventilation and visibility in addition to being strong. The initial designs of wire were crude and diversified.

1. Boom in Poultry Farming:

The increased demand for chicken and eggs in the late 1800s led to a notable rise in the production of poultry. With an increasing number of individuals raising chickens, there was a need for a type of fencing that could both efficiently contain the birds and act as a barrier against potential predators.2. Chicken Wire's Creation:

Although the precise creator of wire is unknown, it is thought to have appeared in the late 19th or early 20th century. Its invention most likely sprang from the practical demands of chicken farmers looking for a cost-effective and adaptable fencing option.3. Advancement and Enhancement:

At first, chicken wire was only a simple mesh made of thin, galvanized steel wires that were twisted or woven together. As manufacturing techniques advanced, so did the design, which now offers increased functionality and durability.4. Initial Uses:

Creating enclosures for chickens with adequate air and visibility, while shielding them from predators, was the main use of chicken wire. Because of its flexibility and light weight, it was the material of choice for enclosing huge areas at a low cost.5. Manufacturing for Commercial Use:

Chicken wire went from being a handmade item to being manufactured commercially as demand for it grew. Due to the mass production made possible by this change, a wider range of farmers and households could now afford it.6. Beyond Chickens:

Although chicken wire was first intended for use in poultry enclosures, its adaptability led to its use in a number of other contexts. It gained popularity in crafts, gardening, and even as a material for small animal fencing.7. Contemporary Modifications:

Modern manufacturing processes use cutting-edge materials and technologies to produce chicken wire that comes in a variety of sizes, gauges, and coating options. Contemporary chicken wire is employed in building, landscaping, and creative endeavors in addition to conventional farming.Chicken wire development and its evolution over time

Original Development:

In the late 19th century, as the need for useful fencing solutions in poultry raising increased, chicken wire was first created. People needed a practical and affordable means to cage and protect their chickens, yet the particular inventor and time frame are not well known.

The original chicken wire was made of thin, twisted, or braided galvanized steel wires to create a mesh. It was a very simple construction. This structure’s flexibility and light weight made it simple to assemble and adjust to different situations, which made it an affordable option for enclosing huge regions.

Evolution over Time:

As chicken raising grew, so did the demand for fencing materials that were more resilient and adaptable. Over time, considerable advancements in the manufacturing process were made to chicken wire, increasing its robustness and usefulness. Innovations in coatings, weaving methods, and materials have all contributed to the evolution of chicken wire.

Materials:

Afterwards, additional materials giving varying degrees of durability and corrosion resistance, such as plastic and aluminum, were added to the original galvanized steel wires.

Weaving Methods:

To improve the overall strength of the chicken wire, manufacturers improved the weaving methods to produce meshes that were tighter and more secure.

Coatings:

Contemporary chicken wire frequently has protective coatings applied to increase its longevity and rust resistance. Depending on the intended application, these coatings could be made of zinc, PVC, or other materials.Adaptation to Different Uses:

Although chicken wire was first created for enclosures for poultry, it has evolved to be used in a variety of applications. In addition to its usage in farming, chicken wire was also used for gardening, small animal fencing, and craft endeavors including arts and crafts. The broad appeal of chicken wire in both rural and urban environments can be attributed to its adaptability and affordability.

Commercial Production:

Chicken wire went from being a handmade product to being produced commercially as demand for it grew. Because of this change in direction, chicken wire could now be produced in large quantities and be more widely available to a wider spectrum of consumers, including farmers, homes, and businesses.

In the end, the practical needs of poultry producers looking for an efficient fencing solution led to the invention of chicken wire. Its development over time involves advancements in coatings, weaving methods, and materials, making it a widely-used and adaptable material for a variety of uses outside of its initial intended usage.

The materials used in making chicken wire

Although other materials can also be utilized, galvanized steel is commonly used to make chicken wire. The main component is thin steel wire that has been zinc-coated to improve its resistance against corrosion. The wire is strengthened and made to last thanks to its galvanized steel. Apart from steel, materials such as aluminum or plastic can also be used to make chicken wire, providing varying degrees of longevity and resistance to corrosion. The material selection is influenced by various aspects, including the intended purpose, environmental factors, and cost considerations.

The manufacturing process and how it contributes to its durability.

Several phases are involved in the manufacturing process of chicken wire, which enhances its durability:

- Diagram of wire: To reduce the raw material’s diameter, it is first drawn through a sequence of dies, usually made of steel. The long, thin wires that are produced as a result will be used to create the mesh.

- The process of galvanization The drawn wires are subsequently galvanized, which is the application of a zinc coating. This is either electroplating the wires to impart a zinc coating or submerging them in a bath of molten zinc. The steel is shielded from rust and other external factors by the zinc coating, which offers corrosion resistance.

- Textile Arts: The distinctive hexagonal mesh design of chicken wire is created by weaving or twisting the coated wires together. The final product’s strength and flexibility are influenced by the weaving process, which also establishes the mesh’s tightness and spacing.

- The annealing process The chicken wire may be heated and then progressively cooled during the annealing process, which comes after weaving. This increases the material’s flexibility and releases internal strains, which makes it simpler to handle during installation.

- Alternatives for Coating: For further protection, certain chicken wire products could go through additional coating procedures. This can include applying PVC coating or other specialist coatings to increase toughness, offer more corrosion resistance, or boost visibility by including color.

- Inspection of Quality: Quality control procedures are used during the manufacturing process to guarantee that the chicken wire satisfies industry requirements. This include determining the product’s overall strength, examining the weave for consistency, and measuring the thickness of the zinc coating.

- Partially responsible for durability

- Enhancing the longevity of chicken wire is mostly dependent on the galvanization process. As a sacrificial layer, the zinc coating corrodes over time to shield the steel underneath. By doing this, the chicken wire’s lifespan is greatly increased and it becomes more resistant to weathering and rust.

The primary purpose of chicken wire, which is often used in poultry farming.

Chicken wire is largely used in poultry farming, where it serves a number of vital functions in the upkeep of poultry cages. The following are important facets of its main objective in chicken farming:

- Poultry Enclosure: Building cages for poultry, such as chickens, ducks, and other small birds, is the main use of chicken wire. It serves as a barrier to keep the birds in the area that has been set apart, keeping them safe from potential threats and preventing them from straying.

- Protection Against Predators: A barrier made of chicken wire protects against foxes, raccoons, snakes, and prey-seeking birds. Predators are unable to squeeze through or enter the enclosure due to the thin mesh size, protecting the chickens from harm.

- Airflow and Observation: The poultry enclosure can have enough airflow thanks to the open mesh design of the chicken wire. Having enough airflow is essential to keeping the birds’ habitat healthy, particularly in areas with warm weather. Furthermore, the mesh offers vision, making it simple for farmers to keep an eye on the wellbeing and behavior of the chickens.

- Flock Separation: Chicken wire can be used to make distinct enclosures for various flocks or bird species in larger poultry farms. This separation aids in managing the general structure of the chicken farm, controlling breeding, and preventing cross-contamination.

- Garden Defense: Crops and gardens are shielded from chickens by using chicken wire. Farmers can let their birds walk freely about garden areas without sacrificing the quality of their harvests by enclosing the regions with chicken wire. This aids in achieving a balance between conserving important vegetation and free-range farming.

- Provisional Enclosures: Chicken wire is adaptable and simple to erect as makeshift pens or enclosures. This adaptability comes in handy for tasks like bird quarantine, temporary separation, and certain stages of poultry management.

- Economical Resolution: Chicken wire is a cost-effective alternative that appeals to poultry producers, particularly those who operate larger farms. Because of its affordability, farmers can build large, safe enclosures without having to spend a lot of money.

In conclusion, the main function of chicken wire in poultry farming is to offer a workable, affordable, and adaptable way to build enclosures that shield birds from predators, enable enough ventilation, and enable successful flock management. Because of its versatility, it is a mainstay in the chicken business, enhancing the general prosperity and welfare of the birds in a range of farming situations.

How to clean and repair it

To keep chicken wire functional and long-lasting, it must be cleaned and repaired. Cleaning is a rather simple process that entails clearing away any collected organic matter, filth, and debris. To start, use a hose to spray the wire to remove any debris, and then use a brush or a solution of water and mild soap to scrub it clean. After giving it a good rinse, let it air dry.

To fix damage like rips or twisted pieces, chicken wire needs to be repaired. To ensure a safe and smooth connection, patch a tear by bending the wires back into position with pliers. Patching larger tears can be accomplished with extra chicken wire pieces secured with wire ties or twists.

Sections that are crooked or deformed can be carefully straightened with pliers. To preserve structural integrity, add more wire or zip ties to strengthen weak areas.

Frequent inspections aid in the early detection and resolution of problems. Think about painting the chicken wire or using a rust-resistant coating to stop rust. In addition to extending the lifespan of the chicken wire, proper maintenance guarantees a secure environment for poultry or other uses. To maintain chicken wire in top shape for many years to come, simple yet efficient maintenance methods include routine cleaning and preventative repairs.